“AutoBatRec2020”: Smart Recycling of Waste Traction Batteries from Electric Vehicles

High-performance lithium-ion batteries contain valuable raw materials and should not be discarded as waste at the end of their life. The research project AutoBatRec2020 sets out to re-assess the entire battery recycling chain and to identify efficient recycling routines that are ecologically sound, economically viable and readily transferable to industrial scale. An important part is to secure supply of raw materials through the recovery of valuable materials from waste streams.

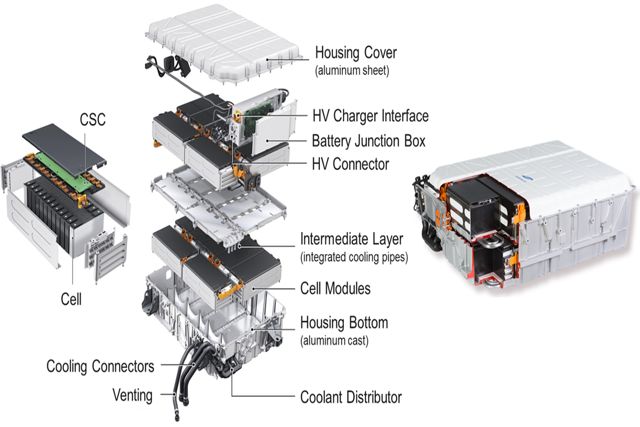

The recycling work starts at the very beginning by having to collect the growing amounts of waste traction batteries that come along with the increase in electric vehicles. Logistic solutions must accomodate for steadily rising amounts. But one of the most challenging problems for the researchers is to overcome the diversity of the many battery systems on the market today, which all end up in the same waste flow and complicate automated processes. The differences between the individual battery systems may be quite significant in terms of design, state and raw materials content.

Another key element is the automated dismantling of the large traction battery systems. Today’s mostly manual labour needs to be replaced by much faster automated processes. The researchers will evaluate all state-of-the-art mechanical crushing and shredding methods as well as new electrohydraulic solutions which can be combined with sophisticated sorting technology for the targeted recovery of the individual material fractions contained in a battery.

As the disassembly may be hazardous because of corrosive, harmful substances or flammable and even explosive components, new concepts have to be established to eliminate risks and ensure a sustainable and eco-friendly recycling of all battery types. Moreover, the partners aim to recover battery components as a whole instead of individual material fractions in order to augment the efficiency and profitability of materials cycles. Last but not least, the researchers will address a smarter design for recycling to facilitate recycling in the future and render it even more efficient.

Project funding

The project “AutoBatRec2020” (Automotive Battery Recycling 2020)is funded by EIT RawMaterials – a Knowledge and Innovation Community of the European Union.

Project launch: 1 January 2018

Term: 3 years

Project partners

- Fraunhofer Institute for Silicate Research ISC – Project Group for Materials Recycling and Resource Strategy IWKS, Germany (coordinator)

- Fraunhofer Institute for Manufacturing Engineering and Automation IPA, Germany

- UMICORE NV, Belgium

- Commissariat à l’énergie atomique et aux énergies alternatives CEA, France

- Technical University Bergakadmie Freiberg, Germany

- ImpulsTec GmbH, Germany

- Daimler AG, Germany

Project manager:

Johannes Öhl

Research Fellow

Energy materials

Fraunhofer Institute for Silicate Research ISC

Fraunhofer Project Group Materials Recycling and Resource Strategies

Rodenbacher Chaussee 4

63457 Hanau

More information about Fraunhofer Project Group Materials Recycling and Resource Strategies IWKS