SOLID – Research at the heart of electromobility

High-performance batteries are the key to electromobility. Europe expects to see a lot more of electric vehicles by 2030. The EU commission is promoting the development of high-performance batteries accordingly. Among the researchers working to make the vision come true are those of the Fraunhofer Institute for Silicate Research ISC in Würzburg, Germany. They take part in the collaborative project SOLID that was recently launched to develop a simple low-cost method for battery mass production via the sol-gel route.

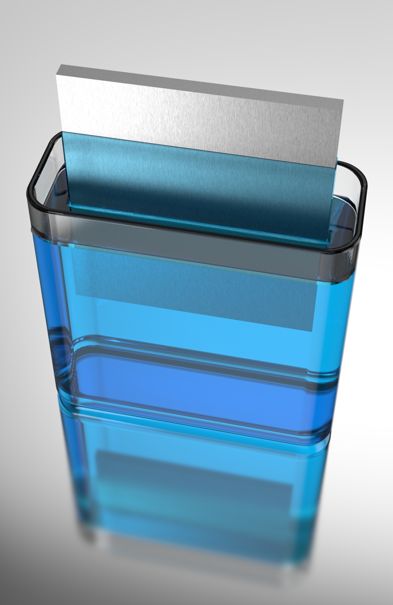

The battery cells from sol-gel are considered a future-proof solution on the path towards safe, low-cost but high-performance batteries able to combine high charging speed with long cycle life. They offer both higher power density and higher voltage than other battery types. A battery of the same weight and volume as a conventional one could store significantly more energy this way. Another benefit is their inorganic construction which means that they are not flammable.

The SOLID team has ambitious aims: in just a year from project launch they want to present the first fully functional single cell based on the new solid state battery concept. The most challenging part will be to realize the required layer thicknesses via the sol-gel route. Layers of the required thicknesses are complex to synthesize, produce and cure and the idea seems to clash with good ion conductivity. But the plan is to employ smart coating method that will not only allow for the desired layer thicknesses but also yield high performance. The task assigned to the Fraunhofer R&D Center Electromobility Bavaria is to produce the current collector layer, the electrolyte layer and the cathode layer via the sol-gel route.

Project funding

The project SOLID (innovative solid state batteries based on sol-gel materials with lithium metal anode and implemented 3D structuring) is funded by the Federal Ministry for Education and Research BMBF. Funding was granted for three years up to September 2020 and totals 3.2 million euros.

Project partners

- VARTA Microbattery GmbH, Ellwangen (coordinator)

- Fraunhofer ISC, Würzburg (co-cordinator)

- Applied Materials WEB Coating GmbH, Alzenau

- COATEMA Coating Machinery GmbH, Dormagen

- LUNOVU GmbH, Herzogenrath

- Fraunhofer ISE, Freiburg