HiQ-CARB project: More sustainable conductive carbon additives for lithium-ion batteries

Sustainable and high-quality conductive additives for lithium-ion batteries are one of the keys to e-mobility in Europe. In view of the increasing demand for rechargeable batteries due to the transition to electric vehicles and renewable energies, the development of innovative and environmentally friendly materials is of central importance. The HiQ-CARB joint project, funded by the European Union/EIT RawMaterials, has taken a major step forward in this key technology for reducing CO2 emissions over the last four years.

The European battery industry needs sustainable materials that meet increasing performance requirements and minimize the environmental impact of battery production and use. The HiQ-CARB research project aims to reduce the amount of conductive additives required in battery electrodes by combining resource-saving carbon nanotubes (CNTs) and carbon-acetylene black from renewable raw materials and also to reduce their carbon footprint. This leads to cost savings and at the same time improves the electrochemical performance of the batteries. The conductive carbon blacks commonly used as conductive additives in the production of battery electrodes are of fossil origin and therefore have an unfavorable CO2 footprint. The HiQ-CARB project benefited from a diverse consortium that contributed unique expertise and resources. Significant advances in the sustainability and performance of lithium-ion batteries have been achieved. The combination of acetylene black and carbon nanotubes has reduced the amount of additives required, resulting in cost-effective and high-performance batteries.

Sustainable resources and material efficiency for a lower environmental impact

Project work to date has included the development of the most effective composition for the new conductive additives, the upscaling of production processes, comprehensive material evaluations and a life cycle analysis (LCA) carried out by the University of Bordeaux. Cooperation with partners such as the Fraunhofer Institute for Silicate Research ISC, Aalto University and battery start-up CustomCells Itzehoe GmbH was crucial in evaluating the materials at both laboratory and pilot scale to ensure their suitability for practical applications.

In addition to upscaling carbon production, evaluating materials and training specialists, the project partners were also tasked with developing a market strategy in order to transfer the knowledge gained to industrial implementation. The key materials include the acetylene-based conductive carbon black particles produced by the company ORION S. A. and the resource-saving CNTs produced by the company ARKEMA. Both materials can be produced in substantial quantities, ranging from several tenths of tons to thousands of tons and have been evaluated by the partners in terms of their properties and environmental impact when used in battery materials.

Successful proof: new additives with a lower CO2 footprint can be integrated into production

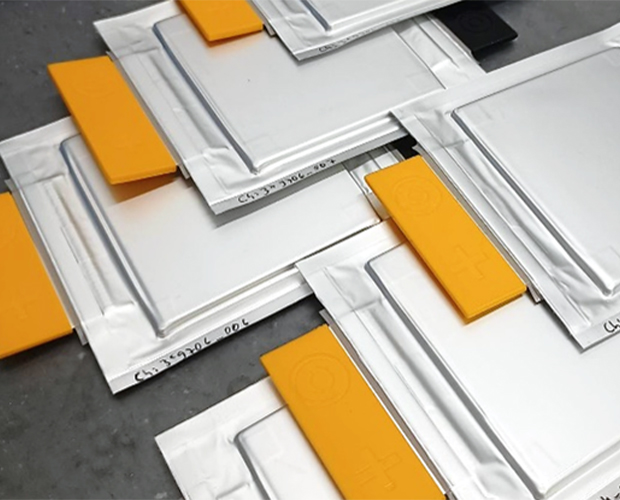

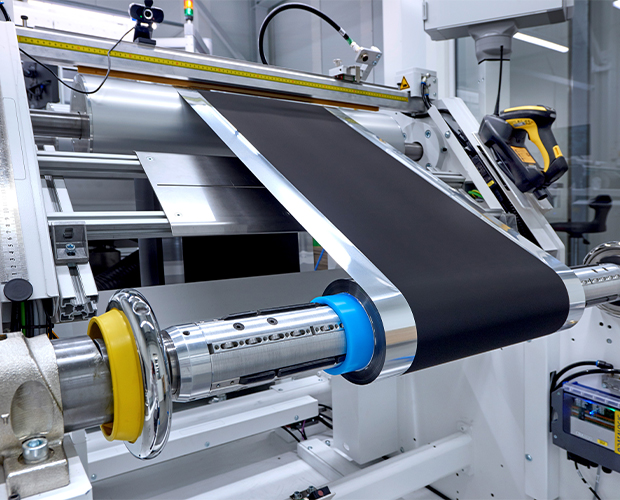

The combination of carbon additives enables an improvement in the achievable conductivities and thus a reduction in the total quantity required in the battery electrodes, which contributes to lighter, more cost-effective and more powerful lithium-ion batteries. Project partner CustomCells provided its production facilities in order to use the new additives directly in battery production instead of the fossil-based conductive carbon black used previously.

"The carbon-based HiQ-CARB additives could be easily integrated into our existing production processes without any significant changes. We achieved very homogeneous coating patterns, which convinced us of their quality," reports project partner Jan Majchel from CustomCells. "As a battery manufacturer based in Germany, CustomCells supports the idea of an innovative battery landscape in Europe with important components from the region. We are delighted about the new opportunities that HiQ-CARB has created."

How "green batteries" benefit from the HiQ-CARB results

The production of acetylene black has been scaled up to over 3000 metric tons and thinner carbon nanotubes have been developed to meet industrial requirements. This has created a basis for more environmentally friendly battery electrode production. Using the new mixtures of conductive, more environmentally friendly carbon additives, the project partners Fraunhofer ISC and Aalto University developed recipes for “high energy” and “high power” cathode materials and processed them into corresponding cathodes. Laboratory-scale evaluation showed good results and, above all, clear advantages over conventional conductive additives.

A clear roadmap for the future production of the more climate-friendly lead additives and the battery cells manufactured with them was outlined. The transfer of optimized cathode formulations to CustomCells ensures the testing and potential commercialization of these innovations.

The comprehensive review of life cycle analyses (LCA) studies carried out by the University of Bordeaux revealed that the production of ORION’s acetylene black has a global warming potential of only around 1.5 kg CO2 equivalent per kilogram (for experts: mainly due to Scope 3 emissions). At 3.5 to 3.9 kg CO2 equivalent per kilogram, the eco-balance of conventionally produced carbon black is significantly higher. These findings underline the need for more sustainable production methods.

The project also supported the training of specialists in the lithium-ion battery value chain.

In summary, the HiQ-CARB project has made significant contributions to promoting sustainable practices in the lithium-ion battery industry. The development and commercialization of innovative conductive additives not only improves battery performance, but also lays the foundation for a more environmentally friendly and economically viable battery manufacturing ecosystem in Europe. The partners are determined to overcome remaining challenges and ensure the successful introduction of these innovations to the market.

The project

HiQ-CARB (High-Quality Conductive Additives for Rechargeable Batteries)

Project duration: 01/2021 - 07/2025

Project funding: by EIT RawMaterials, a body of the European Union

Partners

- Fraunhofer Institute for Silicate Research ISC, Germany (project coordinator)

- Aalto University, Finland

- ARKEMA Group, France

- Customcells Itzehoe GmbH, Germany

- Orion S. A., Germany

- Université de Bordeaux, France