Your Strategic Partner in Battery Material Innovation: The Fraunhofer R&D Center for Electromobility Bavaria

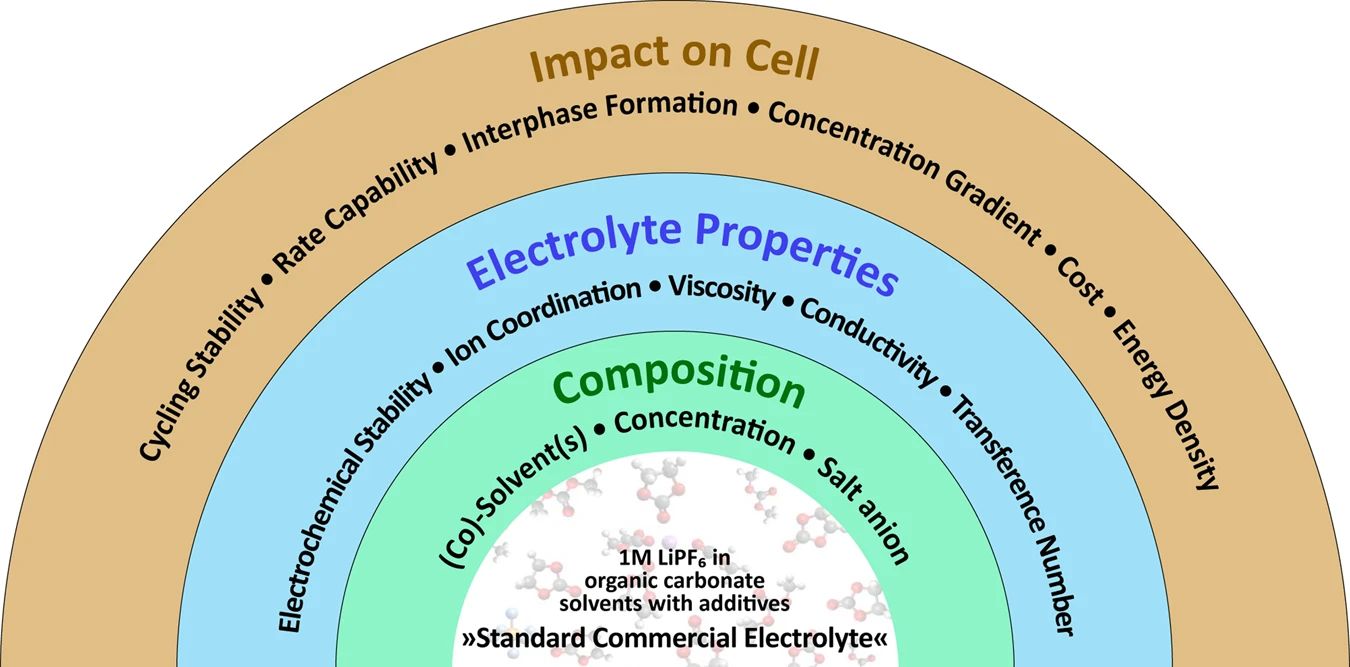

At the Fraunhofer R&D Center for Electromobility Bavaria, we are committed to driving the future of sustainable energy. As your strategic partner, we specialize in the development, testing, and precise optimization of advanced battery materials and components for lithium-ion, sodium-ion, solid-state and lead-acid batteries. Our comprehensive R&D services cater to a diverse range of industries, including battery material suppliers, electrode and battery manufacturers, and battery recyclers.

By collaborating with us, you gain access to state-of-the-art facilities and a team of experts dedicated to pioneering solutions that meet the evolving demands of the battery sector.