ReViSEDBatt - Identifing the causal mechanisms for damage in batteries from mechanical stresses

Battery aging – the gradual decrease in charging capacity over time – is a key factor when it comes to battery range and life span. Relatively little is known about the influence of mechanical stress imposed on batteries during production and operation.

In late 2017, the project “ReViSEDBatt“ was launched to investigate the short and long term effects of mechanical stresses on the cycle life and safety of lithium-ion batteries. As it takes time before the effects of mechanical stresses become apparent in a cell, the task of identifying their root cause is a very challenging one, even more so, since the registration of such effects during actual service is hardly possible at all.

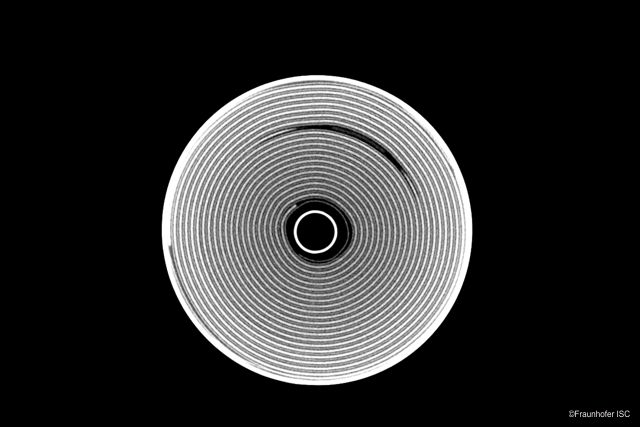

To gather a comprehensive and general understanding of these effects, the project sets out to test all common cell types – cylindric, prismatic, pouch-type and hardcase-type – in near real life static and dynamic stress scenarios and then study resulting damage. Such damage may be due to external mechanical strain at battery module manufacturing or due to the periodic pressure force change within the battery module as a result of the characteristic cell-volume change during charging.

Also under investigation will be production-induced influences, e.g. from the joining technique chosen for battery module production. Another goal is to develop new methods for detecting and locating damages online at an early stage and to integrate the detection algorithms in battery management systems.

As a result it is possible to understand the causal mechanisms in battery cells and modules, to identify the most robust cell type. Ultimately, producers can optimize batteries so they can better cope with everyday stress. This maximizes safety and cycle life of future batteries.

Project funding

The project “ReVisedBatt“ (Resonances, vibrations, shocks and externally imposed mechanical stresses on lithium-ion batteries and new detection methods) is funded by the Federal Ministry for Economic Affairs and Energy (BMWi) within the scope of the 6th Energy Reserach Program.

Project Partners

- Fraunhofer Institute for Silicate Research ISC, Würzburg (coordinator),

- Technical University of Munich, Institute for Electrical Energy Storage Technology EES and Institute for Machine Tools and Industrial Management iwb

- University of Applied Sciences of Munich, Laboratory for Electrical Energy Storage at the Department of Electrical Engineering

- Infineon Technologies AG, Neubiberg

- Hilti Entwicklungsgesellschaft mbH, Kaufering

- HOPPECKE Advanced Battery Technology GmbH, Zwickau

- ThyssenKrupp System Engineering GmbH, Hohenstein-Ernstthal

- TÜV Süd Battery Testing GmbH, Garching

Associated partners

BMW Bayerische Motoren Werke Aktiengesellschaft, München